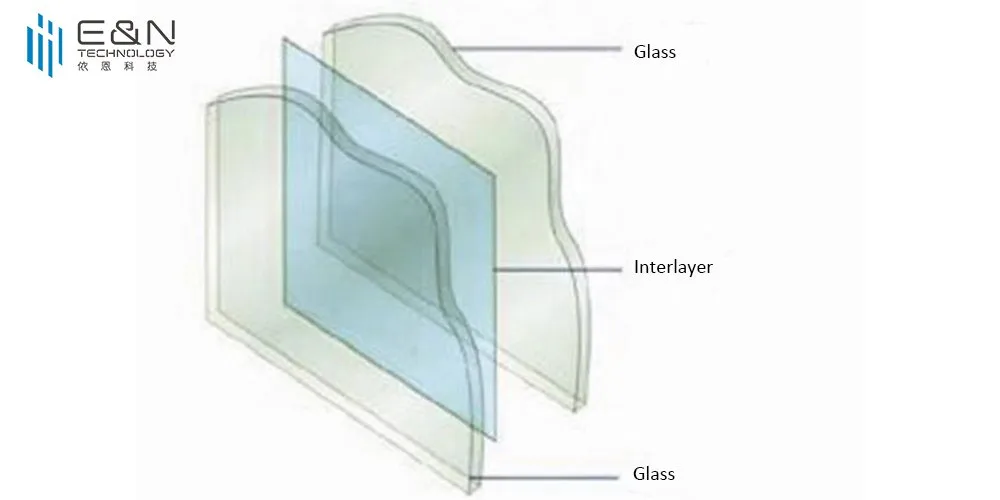

Laminated glass is a composite glass product composed of two or more pieces of glass, with one or more layers of organic polymer intermediate film sandwiched between them. After special high-temperature preloading (or vacuum pumping) and high-temperature and high-pressure processing, the glass and intermediate film are permanently bonded into one.

Laminated glass is widely used in the field of architectural glass, which is also known as safety glass. The common interlayer films of laminated glass are EVA, PVB and SGP.

EVA

The full name of EVA is ethylene vinyl acetate copolymer. Because of its strong water resistance and corrosion resistance, EVA is widely used in packaging film, functional shed film, foamed shoe material, hot melt adhesive, wire and cable, toys and other fields. EVA is usually used as sole material in China.

As the EVA film used for laminated glass, compared with PVB or SGP, EVA has lower melting temperature and better fluidity, and generally has good processing effect at about 110 ℃. Simple vacuuming and heating can meet the production needs of EVA laminated glass.

EVA film has good fluidity, and can be used in the film to make beautiful decorative glass with patterns and patterns. At the same time, it also has good water resistance, but its UV resistance is weak, and it is easy to turn yellow and black under long-term sunlight. Therefore, it is mainly used for indoor partition and decoration.

PVB

The full name of PVB is polyvinyl butyral, which has high transparency, cold resistance and impact resistance. It is the most widely used sandwich material for building glass and automobile glass.

Compared with EVA, the storage and processing technology of PVB interlayer is much more complicated. It is generally required that the temperature of PVB lamination is between 18 ~ 23 ℃, the relative humidity is 18 ~ 23%, and the moisture content of PVB is 0.4 ~ 0.6%. After preheating, rolling or vacuuming, the autoclave shall be used to keep the temperature and pressure for 30 ~ 60 minutes at 120 ~ 130 ℃, 1.0 ~ 1.3mpa. The energy consumption of high-temperature autoclave equipment is huge, which is also the reason why the price of PVB laminated glass is higher than that of EVA glass.

PVB laminated glass has good safety, sound insulation and UV resistance, but the water resistance of PVB is poor, and it is easy to open and fall off in a humid environment for a long time.

SGP

The full name of SGP (sentryglasplus) is ionic intermediate membrane. SGP laminated glass is mainly used for glass daylighting roof, glass external window and curtain wall.

Performance characteristics of SGP film

1. Colorless, with high transparency;

2. Low moisture absorption to prevent water molecules from invading the adhesive layer, generating bubbles or degumming;

3. It has good thermal stability and can withstand temperature changes without degumming of the adhesive layer or damage of the glass to ensure the safety of the laminated glass;

4. It has good light stability to ensure that the sandwich material is not easy to change color or brittle under the action of light, and to ensure the optical performance of the sandwich glass;

5.It has good adhesive force. When the glass is impacted and broken, the glass will not fall off to ensure personal safety;

6.It has good elasticity to increase the penetration resistance and vibration absorption performance of laminated glass.

Performance comparison between PVB and SGP

1. Excellent mechanical properties and high strength. The bearing capacity of SGP laminated glass is twice that of PVB laminated glass with the same thickness; At the same time, the bending deflection of SGP laminated glass is only 1 / 4 of that of PVB laminated glass under the same load and thickness.

2. Tear strength. Under the same thickness, the tear strength of PVB laminated film is 5 times that of PVB. Even if the glass is broken, the SGP film can bond the broken glass to form a temporary structure after damage. Its bending deformation is small, and it can bear a certain amount of load without falling down.

3.Strong stability and moisture resistance. SGP laminated film itself is colorless and transparent, and has good weather resistance and is not easy to yellowing. The yellowing coefficient of SGP film is less than 1.5, while the yellowing coefficient of PVB film is 6 ~ 12. Therefore, SGP is used more in ultra white interlayer.

Although the production process of SGP is similar to that of PVB, the terminal price is high, so it is not widely used in China and its recognition is low.

Disclaimer: This article is reprinted on our website to provide readers with more news information. The contents involved do not constitute investment and consumption suggestions, but are for readers' reference only.