Switchable glass, also called PDLC glass, smart glass, privacy glass. It is composed of one liquid crystal switchable film(also calls PDLC film) and two sheets of glass using special EPD EVA film bonding together under high-pressure & high-temperature.

|

EPD38PL:

|

|

|

EPD76PL:

|

|

|

EPD-PL:

|

|

Main Characteristic:

1.Excellent UV blocking function protects the PDLC film inside the glass from UV damage.

2.High transparency, low attenuation value, effectively ensure the light transmittance of PDLC glass,has a perfectly stable solar control system. (low degradation under UV irradiation)

3.It has extremely high bonding strength to glass and PDLC film, which not only improves the breaking safety of glass and the ability to retain fragments, but also effectively ensures the structural integrity of the finished PDLC glass without delamination.

4.Low yellowing index to ensure that the PDLC glass does not have obvious yellowing phenomenon in the later period of use, and continues to maintain its beautiful appearance.

5.High strength, high hardness, strong weather resistance, low water absorption, effectively protect the PDLC film, and effectively ensure the overall service life of the PDLC glass.

Application:

Space scene applications with privacy requirements, such as: conference rooms, offices or glass partitions, doors and windows, curtain walls and multimedia projection scene applications.

Product Performance Parameter List:

|

Test item |

Test method |

EPD-PL |

|

Transmittance |

ISO527-3 |

>91% |

|

Haze |

E&N Laboratory |

<0.26% |

|

UV blocked rate |

280-380nm |

>99% |

|

Tensile strength |

ISO527-3 |

>19MPa |

|

Adhesion with glass |

ISO-8510 |

>82N/cm |

|

Elongation at break |

ISO527-3 |

≥800% |

|

Cross-linking rate |

E&N Laboratory |

>85% |

|

Water absorption |

ASTMAD570 |

≤0.1% |

|

High temperature test 4hrs 100℃ |

EN 14449/EN1SO12543 |

No visible change |

|

Humidity resistance 85℃ 85%RH 1000hrs |

ENISO12543 |

Haze appeared just 2.5cm from the edge without bubbles or delamination |

|

UV radiation test UVA340 60℃ 65%RH 2000hrs |

EN14449/EN572 |

Yellowing index:Δ<1 |

|

Pendulum test(hight:1200mm) |

EN14449/EN 12600 |

Qualified |

|

Ball impact peeling resistance(hight:4m) |

GB-15763.3-2009 |

Qualified |

Note:the information and relevant data listed in this article are established in the laboratory of the company's technical department,and their contents are correct based on the turth.However,we will not make any statment or guarantee on the integrity or accuracy of the listed information and data.We provide the content of this article on the condition that it is for the user's reference only,and before using it,decide whether the information and data are suitable for their own purpose of use.In no event shall we be liable or liable for damages of any nature whatsoever arising out of the use of or reliance on the content of this document or the products mentioned herein.

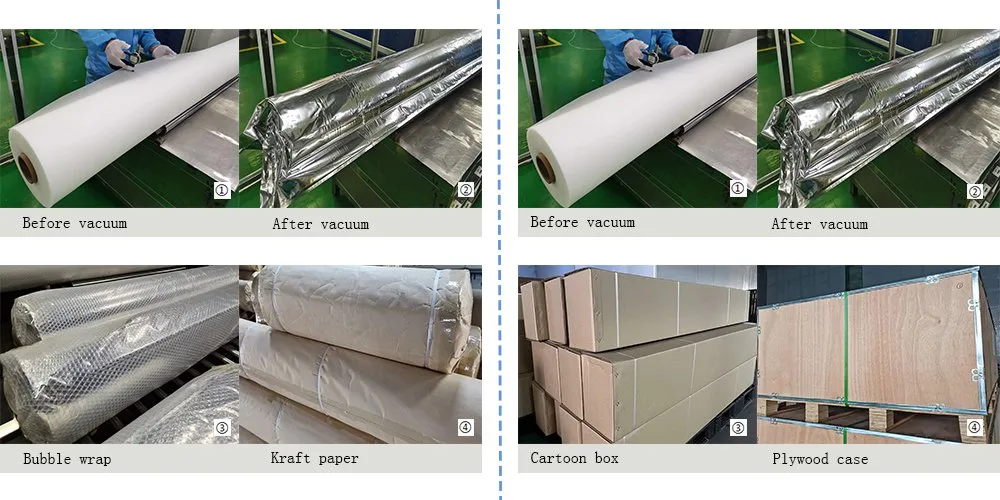

Packing Specification:

1.Without plywood case: tinfoil vacuum + bubble wrap + composite kraft paper

2.With plywood case: tinfoil vacuum + carton box + plywood case

Shelf Life of Product:

1 year

Preparation Before Laminating:

1. Clean and fully dry the glass, there should be no particle dust or oil on the glass surface, EVA film and other intermediate materials are spare.

2. After opening the furnace, cool down for 3~5 minutes, until the vacuum value reaches -0.095MPa, close the furnace door and officially heat.

Parameter setting:

|

First Step |

Second Step |

Full Vacuum Retention |

Temperature Out of Furnace |

|

60℃—20mins |

120℃—80mins |

-0.095MPa |

<50℃ |

The above-mentioned temperature refers to the glass surface temperature.This lamination parameter is suitable for laminated glass with 5mm+0.76EVA+PDLC+0.76EVA+5mm structure.The specific conditions should be adjusted according to the difference of lamination equipment,temperature and humidity,glass thickness,and middle layer material.

1.Why EPD-PL is the best choice with switchable glass lamination?

Because the EPD-PL film raw material is soft,and it has high flow that can be better laminated with smart film. And EPD-PL has best transparency, which is possible to make sure its extra clear when power on.

2.Can I use other ordinary EVA film for switchable glass lamination?

Yes,it is OK,but the transparency is not as good as the film which is special for it.

3.Does the film turn yellow after using for a while?

No,the film is stable even a long term electricity.

4.What is standard size of the film?

The standard size is 2.3m width,but the maximum size is 2.6m width.

5.How many rolls packed in one box?

It will be 6 rolls or 8 rolls usually, sometimes it is 10 rolls.