EN white series EVA films are available in different white colors, and the color can be adjusted according to customer requirements. In addition, EN white series EVA films are cross-linked products and can be used outdoors.

|

EN38S:

|

|

|

EN38Y:

|

|

|

EN38Y2:

|

|

|

EN38C:

|

|

|

EN38C2:

|

|

|

EN38D:

|

|

1.EN white series products are cross-linked products and can be used outdoors

2.Excellent weather resistance

3.High temperature and humidity resistance

4.Excellent adhesion to glass

5.Can be installed on bare side

6.The color properties are stable and uniform

Note:The color difference between individual batches is weak.

1.Indoor and outdoor

2.Scope of application:outdoor and indoor decorative glass lamination and glass wired

|

Test item |

Interlayer Model |

Test method |

|||||

|

Jade White (strong) EN-Y |

Jade White (light) EN-Y2 |

Deep jade white EN-S |

Deep White Opaque EN-C |

Super White Opaque EN-C2 |

Sandblasting White EN-D |

||

|

Haze% |

>93 |

>80 |

>95 |

>98 |

>98 |

>97 |

E&N Laboratory |

|

Transmittance% |

<23 |

<41 |

<17 |

<0.6 |

<0.4 |

<3.5 |

ISO527-3 |

|

UV blocked rate% |

>80 |

>70 |

>90 |

>99 |

>99 |

>99 |

280-380nm |

|

Cross-linking rate% |

>80 |

>80 |

>80 |

>80 |

>80 |

>80 |

E&N Laboratory |

|

Adhesion with glassN/cm |

>80 |

>80 |

>80 |

>80 |

>80 |

>80 |

ISO-8510 |

|

Tensile strength MPa |

>17 |

>17 |

>17 |

>17 |

>17 |

>17 |

ISO527-3 |

|

High temperature test 4hrs 100℃ |

No visible change |

EN 14449 EN1SO12543 |

|||||

|

Humidity resistance 85℃ 85%RH 1000hrs |

Haze appeared just 2.5cm from the edge without bubbles or delamination |

ENISO12543 |

|||||

|

UV radiation test UVA340 60℃ 65%RH 2000hrs |

Yellowing index △Yi<1 |

EN14449/EN572 |

|||||

|

Pendulum test (hight:1200mm) |

Qualified |

EN14449 EN 12600 |

|||||

|

Ball impact peeling resistance(hight 4m) |

Qualified |

GB-15763.3-2009 |

|||||

Note:the information and relevant data listed in this article are established in the laboratory of the company's technical department,and their contents are correct based on the turth.However,we will not make any statment or guarantee on the integrity or accuracy of the listed information and data.We provide the content of this article on the condition that it is for the user's reference only,and before using it,decide whether the information and data are suitable for their own purpose of use.In no event shall we be liable or liable for damages of any nature whatsoever arising out of the use of or reliance on the content of this document or the products mentioned herein.

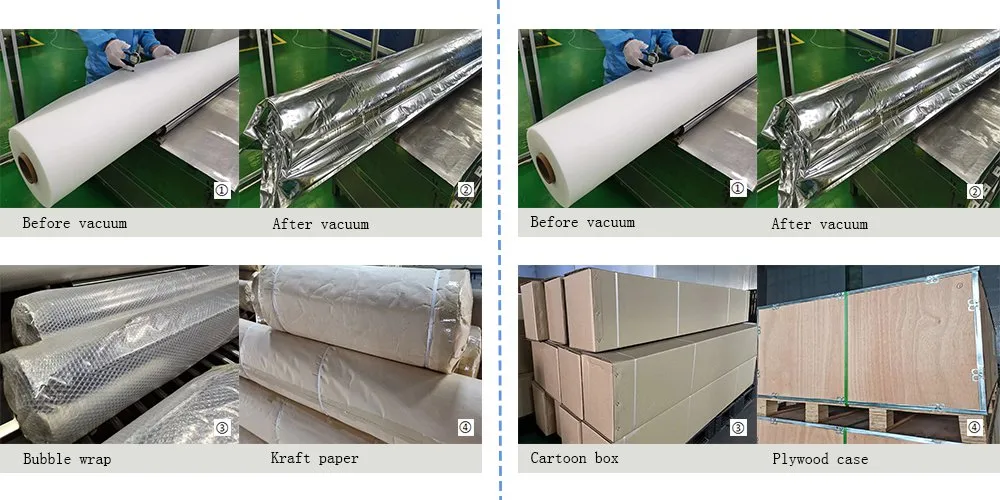

1.Without plywood case: tinfoil vacuum + bubble wrap + composite kraft paper

2.With plywood case: tinfoil vacuum + carton box + plywood case

360 days

1. Clean and fully dry the glass, there should be no particle dust or oil on the glass surface, EVA film and other intermediate materials are spare.

2. After opening the furnace, cool down for 3~5 minutes, until the vacuum value reaches -0.095MPa, close the furnace door and officially heat.

|

First step:60℃—20mins |

|||||

|

Second step:125℃ |

Film thickness |

||||

|

0.38mm |

0.76mm |

1.14mm |

1.52mm |

||

|

Glass Thickness |

4+4mm |

55mins |

60mins |

65mins |

70mins |

|

5+5mm |

60mins |

65mins |

70mins |

75mins |

|

|

6+6mm |

65mins |

70mins |

75mins |

80mins |

|

|

8+8mm |

75mins |

80mins |

85mins |

90mins |

|

|

10+10mm |

85mins |

90mins |

95mins |

100mins |

|

|

Full Vacuum Retention:-0.095MPa |

Temperature Out of Furnace:<50℃ |

||||

The above-mentioned temperature refers to the glass surface temperature.The above parameter settings are for reference only, and the specific parameters should be adjusted according to the laminating equipment, temperature, humidity, glass thickness and intermediate layer material.

1.If it is used for outdoor, it will be yellow turn or de-lamination?

No, it won't.

2.Could the length of it be 100m?

Yes, of course sure.

3. Can I use the opaque film with other color film?

Please take small piece to test first,because eva flow between them is not the same,the color of match might not be even.

4.What is main difference between the EN-Y,EN- C2 and EN-D?

The biggest difference between them is their transparency. The transparency : EN-Y>EN-D>EN-C2.

5.Does the color fade after a long time of exterior application?

No, the color will not fade.